Welded mesh fence, High-Security fence, Double wire fence, Chain link fence, BRC Fence, Airport fence, Euro fence are Chiefence’s main products. All of them are made of galvanized steel wire. That is why we need a zinc or zinc Alloy Coating standard to keep stable quality.

1. Pre-electric galvanizing + Powder Coating

2. Pre-electric galvanizing + PVC Coating

3. Pre-Hot dipped galvanized + Powder Coating

4. Pre-Hot dipped galvanized + PVC Coating

5. Pre-Galfan wire+ Powder Coating

6. Pre-Galfan wire+ PVC Coating

7. Hot Dipped Galvanized after welding only

8. Hot Dipped Galvanized after welding + Powder Coating

9. Hot Dipped Galvanized after welding + Powder Coating

1. Pre-Hot dipped galvanized

2. Pre-Galfan wire

3. Hot dipped galvanized after welding

4. Your requirement

The mass requirement for Zinc coating

| Diameter dmm | Table 1 -Mass of coating | |||||

| A(g/m2) | AB(g/m2) | B(g/m2) | C(g/m2) | D(g/m2) | AX3b(g/m2) | |

| 0.15≤d<0.20 | - | - | 15 | - | 10 | - |

| 0.20≤d<0.25 | 30 | 20 | 20 | 20 | 15 | - |

| 0.25≤d<0.32 | 45 | 30 | 30 | 25 | 15 | - |

| 0.32≤d<0.40 | 60 | 30 | 30 | 25 | 15 | - |

| 0.40≤d<0.50 | 85 | 55 | 40 | 30 | 15 | - |

| 0.50≤d<0.60 | 100 | 70 | 50 | 35 | 20 | - |

| 0.60≤d<0.70 | 115 | 80 | 60 | 40 | 20 | - |

| 0.70≤d<0.80 | 130 | 90 | 60 | 45 | 20 | - |

| 0.80≤d<0.90 | 145 | 100 | 70 | 50 | 20 | - |

| 0.90≤d<1.00 | 155 | 110 | 70 | 55 | 25 | - |

| 1.00≤d<1.20 | 165 | 115 | 80 | 60 | 25 | - |

| 1.20≤d<1.40 | 180 | 125 | 90 | 65 | 25 | 540 |

| 1.40≤d<1.65 | 195 | 135 | 100 | 70 | 30 | 585 |

| 1.65≤d<1.85 | 205 | 145 | 100 | 75 | 30 | 615 |

| 1.85≤d<2.15 | 215 | 155 | 115 | 80 | 40 | 645 |

| 2.15≤d<2.50 | 230 | 170 | 125 | 85 | 45 | 690 |

| 2.50≤d<2.80 | 245 | 185 | 125 | 95 | 45 | 735 |

| 2.80≤d<3.20 | 255 | 195 | 135 | 100 | 50 | 765 |

| 3.20≤d<3.80 | 265 | 210 | 135 | 105 | 60 | 795 |

| 3.80≤d<4.40 | 275 | 220 | 135 | 110 | 60 | 825 |

| 4.40≤d<5.20 | 280 | 220 | 150 | 110 | 70 | 840 |

| 5.20≤d<8.20 | 290 | - | - | 110 | 80 | 870 |

| 8.20≤d<10.00 | 300 | - | - | 110 | 80 | 900 |

| l The coating class with a designation starting with A related to thick coatings(Generally Final Coating). Designations ending in B related to classes usually but not always obtained by(zinc coating) and subsequent drawing. Classes C and D are standard classes for low mass coating which are usually produced but not exclusively, produced by hot zinc dipping and then wiping.l A x 3 related to very high mass requirement three times higher than class A. Other multiples of class A are possible and these classes will be identified in the same way e.g A X 4 | ||||||

The mass requirement for a coating of Zn95% Al5%

Diameter d mm | Table 1 -Mass of coating | ||

| A(g/m2) | AB(g/m2) | B(g/m2) | |

| 0.20≤d<0.25 | - | 20 | 20 |

| 0.25≤d<0.40 | - | 30 | 30 |

| 0.40≤d<0.50 | 85 | 40 | 55 |

| 0.50≤d<0.60 | 100 | 50 | 70 |

| 0.60≤d<0.70 | 115 | 60 | 80 |

| 0.70≤d<0.80 | 130 | 60 | 90 |

| 0.80≤d<0.90 | 145 | 70 | 100 |

| 0.90≤d<1.00 | 155 | 70 | 110 |

| 1.00≤d<1.20 | 165 | 80 | 115 |

| 1.20≤d<1.40 | 180 | 90 | 125 |

| 1.40≤d<1.65 | 195 | 100 | 135 |

| 1.65≤d<1.85 | 205 | 100 | 145 |

| 1.85≤d<2.15 | 215 | 115 | 155 |

| 2.15≤d<2.50 | 230 | 125 | 170 |

| 2.50≤d<2.80 | 245 | 125 | 170 |

| 2.80≤d<3.20 | 255 | 135 | 195 |

| 3.20≤d<3.80 | 265 | 135 | 210 |

| 3.80≤d<4.40 | 275 | 135 | 195 |

| 4.40≤d<5.20 | 280 | 150 | 220 |

| 5.20≤d<8.20 | 290 | - | - |

| 8.20≤d<10.00 | 300 | - | - |

NOTE:

| |||

![]() BS EN 10244-2-2001 Zinc or Zinc-Alloy Coatings-print.pdf

BS EN 10244-2-2001 Zinc or Zinc-Alloy Coatings-print.pdf

As a steel fence supplier, I will share it with you.

Sep. 23, 2021

As a steel fence supplier, I will share it with you.

Sep. 23, 2021

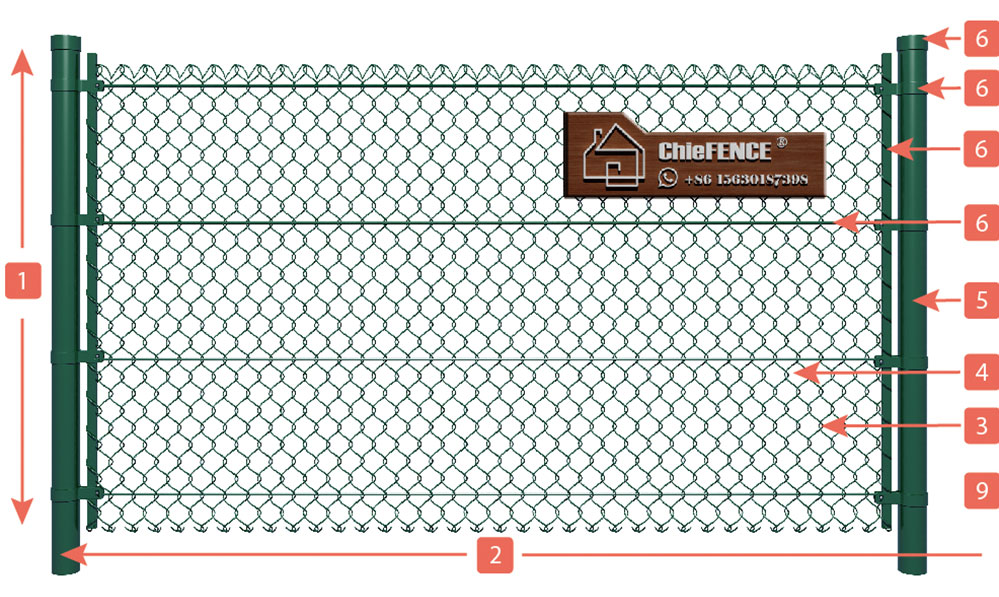

Chain link fencing is an affordable fencing option that you can use to protect your property and keep your pets and children in your yard. But over time, the chain link fence will rust or even break. In order to avoid this situation, you need to properly maintain and maintain it to extend its life.

Aug. 28, 2021

Chain link fencing is an affordable fencing option that you can use to protect your property and keep your pets and children in your yard. But over time, the chain link fence will rust or even break. In order to avoid this situation, you need to properly maintain and maintain it to extend its life.

Aug. 28, 2021

CONTACT US NOW

Copyright © Hebei Loni ChieFence Metal Product Co., Ltd. All Rights Reserved | Sitemap Technical Support: